-

Melt Polymer Candle Filter for High Viscosity Substances Substances

Isihluzi sekhandlela se-polymer esinyibilikayo siyinxalenye ebalulekileyo esetyenziswa kushishino lwefayibha yemichiza yokucoca i-polymer enyibilikayo.I-polymer melt luhlobo olutyhidiweyo lweepholima zokwenziwa, ezisetyenziselwa ukuvelisa iintlobo ezahlukeneyo zemichiza yemichiza efana nepolyester, inayiloni, kunye ne-acrylic.

Eyona njongo yesihluzo sokunyibilika kukususa ukungcola, okunje ngamasuntswana aqinileyo kunye nongcoliseko, ukusuka kwipolymer enyibilikayo phambi kokuba iphinde icutshungulwe ibe yimicu.Oku kungcola kunokuchaphazela kakubi umgangatho wemicu yokugqibela yeekhemikhali kwaye kubangele imiba yemveliso efana nokungalingani, iziphene, kunye nokunciphisa iimpawu zomatshini.

I-melt filter element ifakwe kumgca we-extrusion, apho i-polymer inyibilika inyanzeliswa ngesihluzi ukususa ukungcola.I-polymer ehluziweyo inyibilika emva koko iqhubela phambili kwinkqubo yokujikeleza, apho iqina ibe yimicu eqhubekayo okanye imicu ye-staple.

Ukugcinwa rhoqo kunye nokutshintshwa kwe-melt filter element kubalulekile ukuqinisekisa ukusebenza okuqhubekayo kunye nokusebenza kakuhle kwenkqubo yokuvelisa i-chemical fiber.Oku kunceda ukuphepha ixesha lokunciphisa imveliso, ukuphucula umgangatho wemveliso, kunye nokuqinisekisa ixesha elide lezixhobo zokucoca. -

Isihluzi seOyile yentsimbi engatyiwayo kwiMedia yeMetal

Ukuhluzwa kweoli yinkqubo yokususa ukungcola kunye nokungcola kwioli, ukuvumela ukuba isetyenziswe kwakhona okanye isetyenziswe kwakhona.Ngokuqhelekileyo isetyenziswa kumashishini afana neenqwelo-mafutha, ukuvelisa, kunye nokuveliswa kwamandla.

Kukho iindlela ezininzi zokuhluza i-oyile, kuquka:

Ukuhluzwa koomatshini: Le ndlela isebenzisa izihluzi ezenziwe ngezinto ezifana nephepha, ilaphu, okanye i-mesh ukuze ibambe ngokwasemzimbeni kwaye isuse amasuntswana aqinileyo kwi-oyile.

I-Centrifugal filtration: Kule nkqubo, ioli ijika ngokukhawuleza kwi-centrifuge, idala ukujikeleza kwesantya esiphezulu esahlula amasuntswana anzima kwi-oyile ngamandla e-centrifugal.

Vacuum dehydration: Le ndlela ibandakanya ukubeka i-oyile kwindawo yokucoca, ethoba iqondo lokubila kwamanzi kwaye ibangele ukuba ibe ngumphunga.Oku kunceda ukususa amanzi kunye nokufuma kwioli.

Ukuhluzwa kwe-oyile kubalulekile ekugcineni ukusebenza kunye nobomi bezixhobo ezixhomekeke kwi-oyile yokuthambisa.Inceda ukuthintela ukwakhiwa kwe-sludge kunye ne-deposits, iphucula i-viscosity yeoli kunye nokuzinza kwe-thermal, kwaye ikhusela amacandelo abalulekileyo ekugqokeni nasekudakaleni. -

Isihluzi seGesi yeNsimbi engatyiwayo kwiMetal Media

Injongo yokuhluzwa kwegesi kukuqinisekisa ukuba igesi ecutshungulwayo okanye esetyenziswayo icocekile kwaye ayinamasuntswana, izinto eziqinileyo, ulwelo, kunye nezinye izinto ezingcolisayo ezinokuthoba umgangatho werhasi okanye zichaphazele ukusebenza kakuhle kunye nokusebenza kwezixhobo okanye iinkqubo ezisetyenziswayo. kwi.

Ukuhluzwa kwegesi kunokufezekiswa ngeendlela ezahlukeneyo kunye nobuchwepheshe, kuxhomekeke kwiimfuno ezithile kunye neentlobo zokungcola ezikhoyo.Ezinye iindlela eziqhelekileyo ziquka:

I-Particle Filtration: Oku kubandakanya ukusebenzisa izihluzi ukubambisa ngokwasemzimbeni kunye nokususa amasuntswana aqinileyo kunye nombandela osuka kumjelo werhasi.Iifilitha zingenziwa ngezinto ezifana ne-fiberglass, i-polypropylene, okanye insimbi engenasici, kwaye zikhethwe ngokusekelwe kubukhulu kunye nohlobo lweengqungquthela eziza kususwa.

I-Coalescing Filtration: Le ndlela isetyenziselwa ukususa amathontsi angamalwelo okanye inkungu kwiigesi.Izihluzi ezidibanisayo ziyilelwe ukubamba kunye nokudibanisa amathontsi amancinci angamalwelo abe ngamakhudlwana, ewavumela ukuba atsalwe lula okanye ahlulwe kumjelo werhasi.

Ukhetho lwendlela yokucoca kunye nemidiya ethile yokucoca okanye itekhnoloji ixhomekeke kwizinto ezifana nokwakheka kwegesi, isantya sokuhamba, uxinzelelo, ubushushu, kunye nenqanaba elifunwayo lokuhluza. -

Ikhatriji yesihluzi sentsimbi engatyiwayo

Ikhatriji yokucoca intsimbi yentsimbi yikhatriji yokucoca eyenziwe ngezinto zentsimbi engatyiwa, esetyenziselwa ukuhluza ukungcola kulwelo okanye kwirhasi.Iikhatriji zokucoca insimbi engenasistainless zineengenelo zokuxhathisa i-corrosion, ukumelana nobushushu obuphezulu, ukumelana noxinzelelo, njl.njl., kwaye zisetyenziswa ngokubanzi kukucoca ulwelo, ukuhluzwa kwegesi, ukwahlulwa kolwelo oluqinileyo kunye nezinye iinkqubo kwindawo yoshishino.Iyakwazi ukususa ngokufanelekileyo iincinci ezimisiweyo, ukungcola, i-sediments, njl., kunye nokuphucula ukucoceka kunye nomgangatho wolwelo.Iikhatriji zokucoca insimbi engenasici zihlala zinesakhiwo esine-multi-layer kwaye zizaliswe ngamajelo eendaba ezichanekileyo ezahlukeneyo.Ukuchaneka okufanelekileyo kokucoca kunye nobukhulu kunokukhethwa ngokweemfuno zangempela.Ngenxa yokuqina kunye nokucocwa lula kwezinto zensimbi ezingenasici, i-cartridges ye-filter yensimbi engenasici ingasetyenziselwa ngokuphindaphindiweyo kwaye ibe nobomi obude benkonzo.

Iikhatriji zokucoca intsimbi zisetyenziswa kakhulu kwikhemikhali, kwipetroleum, kumayeza, kukutya, kwisiselo, kunyango lwamanzi nakwamanye amashishini. -

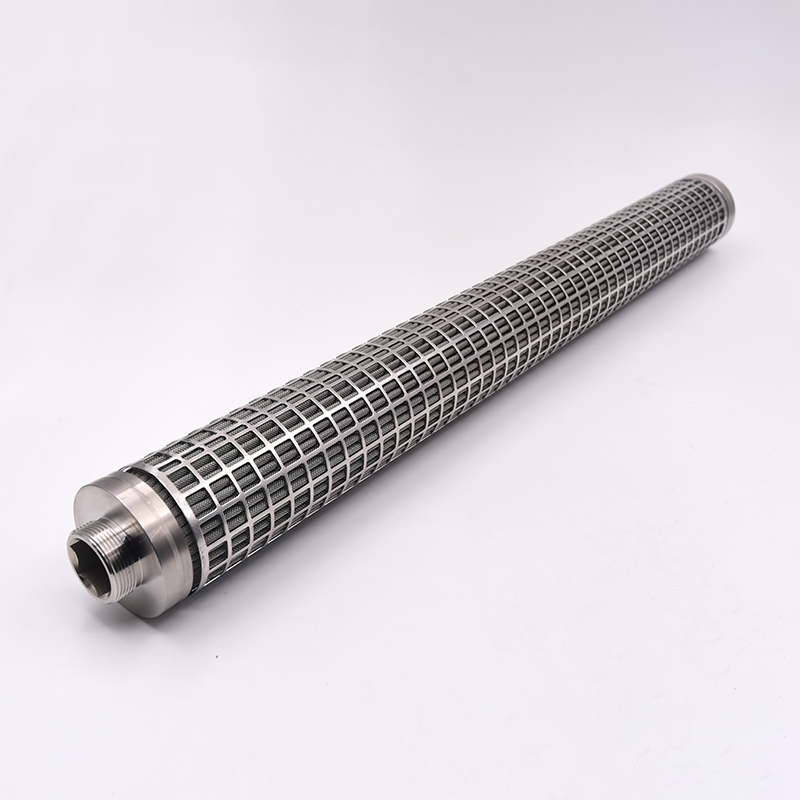

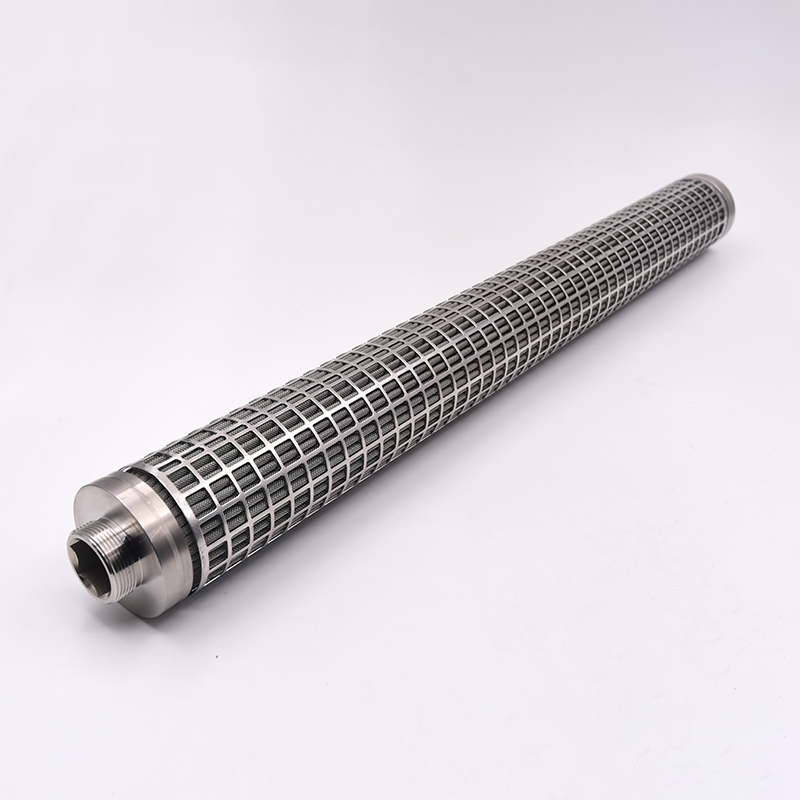

ISintered Wire Mesh Candle Filter

Isihluzi se-sintered wire mesh saziwa ngokusebenza kakuhle kokucoca, amandla okubamba ubumdaka obuphezulu, kunye nokuxhathisa umhlwa kunye namaqondo obushushu aphezulu.Isetyenziswa ngokuqhelekileyo kumashishini ahlukeneyo, afana neoli kunye negesi, ukulungiswa kweekhemikhali, amayeza, ukutya kunye nesiselo, kunye nonyango lwamanzi.

Isihluzi siyilelwe ukususa ukungcola, izinto eziqinileyo, kunye nezingcolisi kulwelo okanye kumjelo werhasi.Ingasetyenziselwa kuzo zombini izicelo zokuhluza ulwelo kunye negesi, ukubonelela ngokusebenza okuthembekileyo nokuhambelanayo kokucoca.Isihluzi socingo olunemingxuma edibeneyo luyakwazi ukugcina amasuntswana ukuya kutsho kwi-sub-micron ubukhulu, nto leyo eyenza ukuba ilungele usetyenziso apho kufuneka ukuhluzwa okulungileyo.

Izihluzi ze-sintered wire mesh zisebenza kakuhle kwaye zithembekile izisombululo zokucoca ezibonelela ngokusebenza okugqwesileyo kunye nobomi benkonzo ende kuluhlu olubanzi lwezicelo zamashishini. -

Isihluzi seBhaskithi kunye neConical Filter

Ibhaskithi yokucoca sisixhobo esisetyenziselwa ukuhluza okuqinileyo kulwelo okanye kwiigesi.Ngokwesiqhelo siquka isingxobo okanye isitya esimilise okwebhaskithi esinemathiriyeli enemingxuma, enje ngomnatha okanye isinyithi esinemingxuma, ukubambisa izinto eziqinileyo ngelixa uvumela ulwelo okanye irhasi ukuba idlule.

Iibhaskithi zokucoca ziqhele ukusetyenziswa kumashishini ahlukeneyo, kubandakanywa ukuvelisa, i-oyile kunye negesi, ukutya kunye nesiselo, kunye nonyango lwamanzi.Zihlala zifakwe kwimibhobho okanye kwiinqanawa zokususa i-debris, amasuntswana, okanye i-contaminants kwi-fluid stream.

Isihluzi seconical luhlobo lwesixhobo sokuhluza esinemilo eyiconical.Yenzelwe ngokukodwa ukuhluza ulwelo okanye iigesi kunye nokususa ukungcola okanye amasuntswana kuzo.

Imilo yeconical yesihluzi inenzuzo njengoko ivumela ukuhluzwa okusebenzayo kunye nokwandisa indawo ekhoyo yokunxibelelana nolwelo.Olu yilo lukhuthaza ukubanjiswa okusebenzayo okanye ukugcinwa kwamasuntswana ngelixa uvumela ulwelo oluhluziweyo ukuba ludlule. -

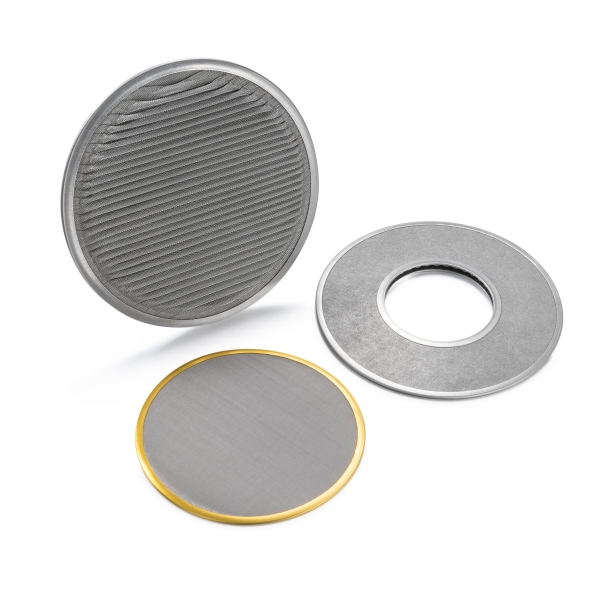

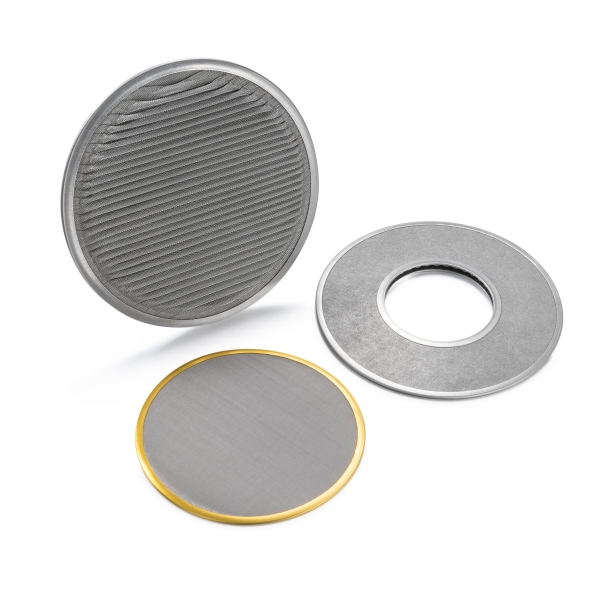

Izihluzi zeDisc zeLeaf zoHluzo lwefilimu yePolymer

Iifilimu zePolymer zinoluhlu olubanzi lwezicelo ngenxa yeempawu zazo kwaye zisetyenziswa ngokuqhelekileyo kumashishini afana nokupakishwa, i-electronics, i-automotive, kunye ne-biomedical njengeengubo ezikhuselayo, izithintelo zemiqobo, i-encapsulation ye-electronic device, okanye njenge-substrates ye-flexible displays.

Njengoko ifilimu ye-polymer ibhekisa kwiphepha elibhityileyo okanye isambatho esenziwe ngezinto zepolymer.Injongo ephambili yokucoca i-disc yeqabunga kwi-filtration yefilimu ye-polymer kukususa ukungcola, ukungcola, kunye neengqungquthela ezivela kwi-polymer inyibilika okanye isisombululo ngaphambi kwenkqubo yokubunjwa kwefilimu.Oku kunceda ukuqinisekisa ukuveliswa kweefilimu zepolymer ezikumgangatho ophezulu kunye nezingenasiphako.

-

I-Metal Powder ye-Polymer Filtration

I-Metal powder ekhoyo kwiincinci ezahlukeneyo ezenziwe kwizinto ezahlukeneyo, ezifana ne-nickel, i-chromium, i-silicon, i-Manganese inamandla aphezulu kunye nokuzinza kweekhemikhali eziphezulu njengemidiya yokucoca ngexesha lenkqubo ye-polyester kunye ne-polyamide yarn spinning.Isanti ye-Futai yensimbi engenasici inemilo eyongezelelweyo engaqhelekanga kunye neempawu ezingaphezulu kwendawo yokubamba ngokufanelekileyo kunye nokugcina amaqhekeza avela kwi-polymer etyhidiweyo ukwenzela ukunciphisa i-clog ye-spinnerets kunye nokuqhekeka kwentambo.

Ukukhethwa komgubo wensimbi engenasici kwi-polymer filtration kufuneka kuthathelwe ingqalelo izinto ezinjengokuhambelana nezinto zepolymer, uluhlu olufunwayo lobungakanani besuntswana, ukusebenza kakuhle kokucoca, kunye naziphi na iikhemikhali ezithile okanye iimfuno zokusingqongileyo.

-

I-Spin Pack Filter kwiMedia yeMetal

I-spin pack filter kwimidiya yesinyithi luhlobo lokucoca olusetyenziswa kumashishini ahlukeneyo, ngakumbi kwiinkqubo zokuvelisa i-polymer.Isisombululo sinokuba yioli, igesi, amanzi, igrisi, ulwelo, i-polymer okanye naluphi na uhlobo lwesisombululo esihambayo kulo naliphi na iqondo lobushushu.Iqulethe i-mesh yocingo lwentsimbi okanye isikrini esijikwe kuyo nayiphi na imilo, efana ne-cylindrical, uxande, isikwere, imilo embhoxo okanye ezinye.Esi sihluzo sepakethe sifakwe kwi-filtration system ukususa ukungcola kunye namaqhekeza kwisisombululo.Imidiya yesinyithi inika amandla aphezulu kunye nokuqina, ivumela isihluzo ukuba simelane nokushisa okuphezulu kunye noxinzelelo.