I-PET PA PP etyhidiweyo i-polymer ephezulu idinga ukuhluzwa ngaphambi kokuba i-chemical fiber spinning isuse ukungcola kunye ne-gel particles efakwe kwi-melt ukukhusela ukuxutywa kwe-spinneret hole;xa i-polymer enyibilikayo ihamba nge-spin pack screen layer, ukuxhathisa kwenziwa, ukuze i-Friction enyibilikayo ivelise ubushushu, ubushushu buphakame, kunye neempawu ze-rheological zokunyibilika ziphuculwe.Ngelo xesha, ukunyibilika kuxutywe ngokupheleleyo ukukhusela ukungafani kwe-viscosity phakathi kokunyibilika;i-melt isasazwa ngokulinganayo kumngxuma ngamnye omncinci we-spinneret;ngokunyuka kwexesha lokusetyenziswa kwesihluzo se-spin pack, ukungcola kwi-mesh pack filter layer kuya kwanda, kwaye uxinzelelo lwendibano luya kunyuka ngokuthe ngcembe.Uxinzelelo lokunyusa isantya ngokukhawuleza, kwaye ubomi benkonzo yendibano bufutshane.Xa indibano iphakama kuxinzelelo oluthile, kuyimfuneko ukutshintsha indibano ngexesha, ngaphandle koko, ipompo yemitha iyachithwa, okanye i-spinneret ikhubazekile, okanye ukuvuza kwenzeka.

I-PET PA PP etyhidiweyo i-polymer ephezulu idinga ukuhluzwa ngaphambi kokuba i-chemical fiber spinning isuse ukungcola kunye ne-gel particles efakwe kwi-melt ukukhusela ukuxutywa kwe-spinneret hole;xa i-polymer enyibilikayo ihamba nge-spin pack screen layer, ukuxhathisa kwenziwa, ukuze i-Friction enyibilikayo ivelise ubushushu, ubushushu buphakame, kunye neempawu ze-rheological zokunyibilika ziphuculwe.Ngelo xesha, ukunyibilika kuxutywe ngokupheleleyo ukukhusela ukungafani kwe-viscosity phakathi kokunyibilika;i-melt isasazwa ngokulinganayo kumngxuma ngamnye omncinci we-spinneret;ngokunyuka kwexesha lokusetyenziswa kwesihluzo se-spin pack, ukungcola kwi-mesh pack filter layer kuya kwanda, kwaye uxinzelelo lwendibano luya kunyuka ngokuthe ngcembe.Uxinzelelo lokunyusa isantya ngokukhawuleza, kwaye ubomi benkonzo yendibano bufutshane.Xa indibano iphakama kuxinzelelo oluthile, kuyimfuneko ukutshintsha indibano ngexesha, ngaphandle koko, ipompo yemitha iyachithwa, okanye i-spinneret ikhubazekile, okanye ukuvuza kwenzeka.

Ukhetho lwamacandelo afanelekileyo okucoca lubaluleke kakhulu ekujikelezweni, kwaye imidiya yokucoca amasuntswana ayiyona ibaluleke kakhulu.Kwinkqubo yophuhliso lokusonta, ikwayinkqubo yokufumana isihluzo esifanelekileyo sokucheba.Izinto ezininzi ezaziwayo zokucoca zibandakanya isanti yaselwandle, iitshefu zentsimbi, amaso eglasi, iipleyiti zentsimbi ezinabileyo, kunye namasuntswana esinyithi amile ngendlela engaqhelekanga.

Ukongeza kokungabizi, indawo yokucoca efanelekileyo kufuneka kwaye igcine i-porosity ephezulu kuxinzelelo olufunyenwe ngexesha lokuhluzwa kwe-polymer enyibilikayo.Ukuze kugcinwe i-porosity ephezulu, ibhedi yeengqungquthela ezininzi ze-polymers ezishushu ziqhelekile ukwenza i-gel eqokelela kunye nokunciphisa ukusebenza kakuhle kwe-filtration media media.Ngaloo ndlela, i-particulate metal filtering material ayifanele ifake okanye ifake isandla ekubunjweni kwejel.

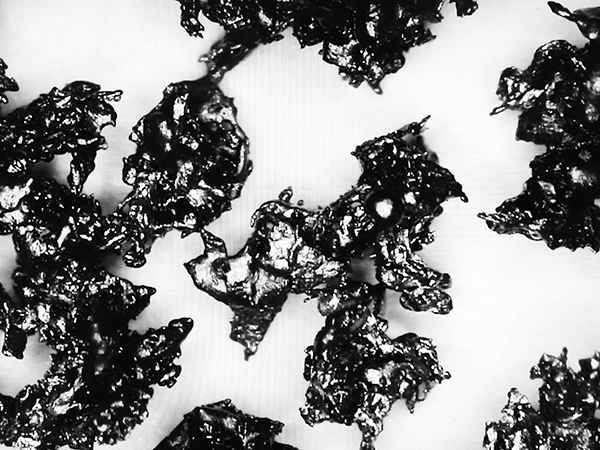

Ifumaneka ngakumbi ukufumana isanti yolwandle, kodwa i-brittle kakhulu kunye nesiphumo sokuba ukuphuhliswa kwamasuntswana amahle kuthanda ukuthintela i-capillaries kwi-spinnerets.Ukongeza, ummandla othile womphezulu wesanti yolwandle ungaphantsi kakhulu kwaye ungaphantsi kwepesenti ye-porosity kuwo nawuphi na umthamo wepakethi yokucoca, ngoko ke uxinzelelo lwepakethi luya kunyuka ngokukhawuleza.Umgubo wentsimbi estainless olungiswa phantsi kweemeko ezithile ubonisa umphezulu ongaqhelekanga kakhulu othi ngokufanelekileyo uxinano olubonakalayo olusezantsi, luthande ukwandisa ukusebenza kakuhle kwawo ukuhluza;phantsi koxinzelelo lokusebenza, ibonisa zombini uxinaniso olubonakalayo kunye nokuphucula ukuxhathisa ukunyanzeliswa kokusebenza kakuhle kokucoca kunye nokuguqulwa kwamasuntswana amancinci okanye angabikho kunye nokuwa.

Ixesha lokuposa: Aug-29-2018