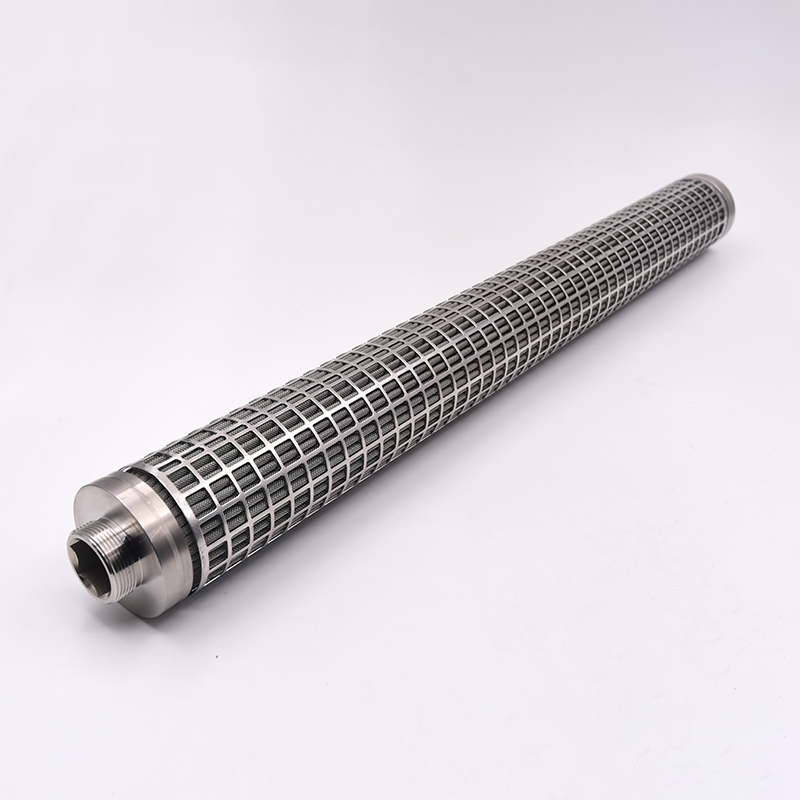

Melt Polymer Candle Filter for High Viscosity Substances Substances

Nyibilikisa isihluzi seKhandlela sePolymer

Isihluzo esinyibilikayo sisixhobo sokucoca isinyithi esidityaniswe yi-argon arc welding.Umaleko wesihluzi wamkela inkqubo yokugoqa yesakhiwo esine-pleat ezininzi, kunye nokuhanjiswa kwepore efanayo kunye nokwanda kwendawo yokucoca.Isihluzi sentsimbi senziwe ngokupheleleyo ngentsimbi engenasici, ngaphandle kokuvuza okanye ukuchithwa okuphakathi.Kwiindawo ezinoxinzelelo oluphezulu, isihluzi sentsimbi engenasiphene samkela uyilo lwamathambo.I-skeleton yangaphakathi kunye nengaphandle iphakamisa kakhulu ukuxhathisa koxinzelelo lwentsimbi yesihluzo se-pleated element.Owona maleko ophambili wesihluzo sePleated Filter ikakhulu sisebenzisa izinto ezimbini: umnatha wocingo lwentsimbi engenastainless kunye nentsimbi engatyiwayo iSintered fiber.Umnatha wocingo lwentsimbi engenastainless lulukwe ngocingo lwentsimbi engatyiwayo.Isihluzi saso esinabileyo sineempawu zeepores ezigudileyo, ukucocwa lula, ukumelana nobushushu obuphezulu, ukuxhathisa ukubola, akukho mesh yocingo ewayo, kunye nomjikelo omde wokuhluza.I-stainless steel sintered fiber sisihluzo esinzulu esenziwe ngeentsinga zentsimbi engenasici kubushushu obuphezulu.Isihluzi saso esine-pleated sineempawu ze-porosity ephezulu, ukunyanzeliswa komoya okulungileyo, amandla okubamba ubumdaka obuqinileyo, kunye nokukwazi ukuvuselela amandla.

Isihluzi se-Melt sisixhobo sokuhluza esisetyenziswa kakhulu kushishino lwefayibha yeekhemikhali ukunyibilika kwepolymer kunye nezinye izinto ezinobunzulu be-viscosity.Umsebenzi walo kukususa ukungcola okuqinileyo okufana neengqungquthela ze-carbonized kunye ne-oxides zetsimbi kwi-melt, ukuphucula ukucoceka kokunyibilika, ukubonelela ngezinto eziphathekayo ezifanelekileyo kwiinkqubo ezisezantsi, kunye nokuqinisekisa ukusebenza okuqhelekileyo kwesihlunu se-melt.

Iimpawu zobuGcisa

1. Ukumelana nokushisa okuphezulu, uxinzelelo oluphezulu kunye nokubola kweekhemikhali.

2. Ukuphefumla okugqwesileyo, umthamo omkhulu wokubamba ukungcola, amandla aphezulu, ukutywinwa kakuhle, ubomi obude, kwaye inokucocwa kwaye isetyenziswe kwakhona ukusetyenziswa ngokuphindaphindiweyo.

3. Indawo yokucoca esongiweyo ngamaxesha angama-3-5 yohlobo lwe-cylindrical.

4. Ubushushu bokusebenza: -60-500℃.

5. Umahluko omkhulu woxinzelelo into yokucoca inokumelana: 10MPa.

IiParameters zeSicelo seMveliso

1. Uxinzelelo lokusebenza: 30Mpa.

2. Ubushushu bokusebenza: 300℃.

3. Umthamo wokubamba ubumdaka: 16.9~41mg/cm².

Indlela yoQhagamshelwano lweMveliso

I-interface esemgangathweni (efana ne-222, i-220, i-226) uxhulumaniso olukhawulezayo lwe-interface, uxhumano lwe-threaded, uxhumano lwe-flange, uxhulumaniso lwentonga yokubopha, ujongano olukhethekileyo olulungiselelwe.

IiNdawo zokuSebenza

1. I-Petrochemical: Ukucoca, ukuveliswa kweekhemikhali kunye nokwahlula kunye nokubuyiswa kweemveliso eziphakathi.

2. I-Metallurgy: isetyenziselwa ukuhluzwa kweenkqubo ze-hydraulic ze-rolling mills kunye noomatshini abaqhubekayo bokuphosa.

3. I-Textile: Ukuhlanjululwa kunye ne-uniform filtration ye-polyester iyancibilika ngexesha lokudweba.

4. I-Electronics kunye ne-pharmaceuticals: unyango lwangaphambili kunye nokuhluzwa kwamanzi e-osmosis e-reverse kunye namanzi adibeneyo, unyango lwangaphambili kunye nokucoca ukucoca ulwelo kunye ne-glucose.

5. Amandla e-thermal kunye namandla enyukliya: ukucocwa kweenkqubo zokuthambisa, iinkqubo zokulawula isantya, iinkqubo zokulawula i-bypass ye-injini yegesi kunye neebhoyili, ukucocwa kweempompo zokubonelela ngamanzi, iifeni kunye neenkqubo zokususa uthuli.

Imveliso engakumbi