Inkqubo yoHluzo yokuNyibilika kwePolymer yokucoca

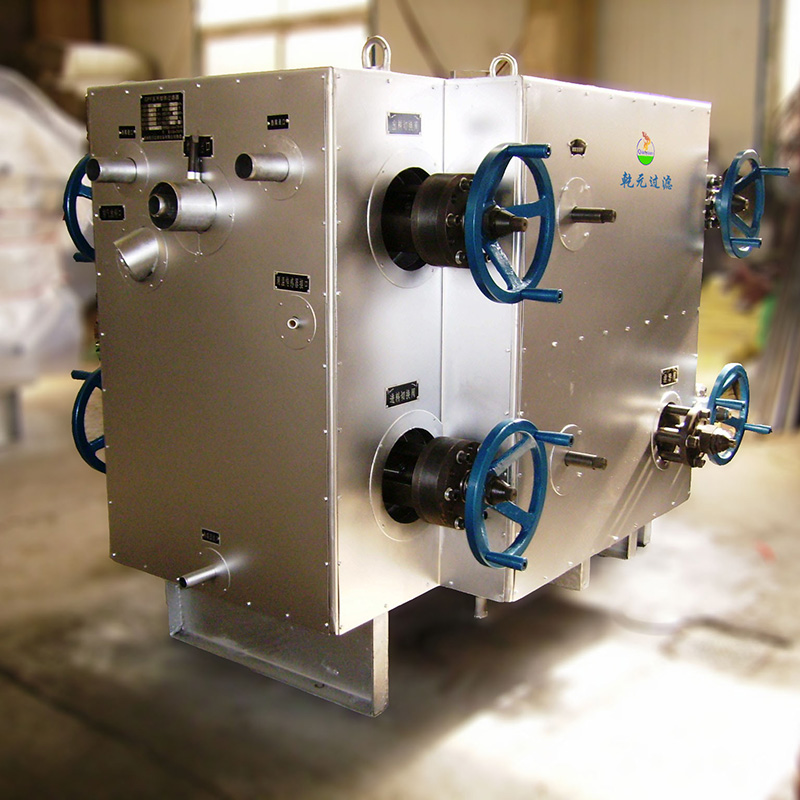

I-Melt Polymer Filtration System

Inkqubo yokuhluza i-polymer enyibilikayo ibalulekile kwizicelo ezininzi apho iipolymers zicutshungulwa okanye zisetyenziswa, njengokuveliswa kwe-PET / PA / PP imboni yepolymer, i-polymerizaton yangaphambili, i-polymerization yokugqibela, i-filament yarn, i-polyester staple fiber spinning, iifilimu ze-BOPET / BOPP , okanye inwebu.Le nkqubo inceda ukususa ukungcola, ukungcola, kunye neengqungquthela ezichaphazela i-viscosity kwi-polymer etyhidiweyo, iqinisekisa umgangatho kunye nokuhambelana kwemveliso yokugqibela.

Ukuze kuphuculwe umgangatho we-polymer enyibilikayo kunye nokwandisa ubomi benkonzo yamacandelo e-spin pack, i-filter eqhubekayo yokunyibilika (CPF) ifakwe kumbhobho oyintloko wokunyibilika.Iyakwazi ukususa amasuntswana okungcola komatshini kunye nobubanzi obungaphezulu kwe-20-15μm kwi-melt, kwaye inomsebenzi we-homogenizing inyibilika.Ngokuqhelekileyo inkqubo yokucoca iquka amagumbi amabini okucoca, kwaye iivalve zendlela-ntathu ziqhagamshelwe kumbhobho onyibilikayo.Iivalve zeendlela ezintathu zingatshintshwa ngamaxesha athile ukuze zitshintshe ukusetyenziswa kwamagumbi okucoca ukuqinisekisa ukucoca okuqhubekayo.Izindlu zegumbi lokucoca zifakwe kwisiqwenga esinye kunye nentsimbi engenasici.Isihluzi sendawo enkulu senziwe ngezinto ezininzi ezinepleyiti zokucoca ikhandlela.Into yokucoca ikhandlela ixhaswa yi-cylinder engundoqo enemingxuma, kwaye umaleko wangaphandle uxhotyiswe ngomnatha wesinyithi omnye okanye we-multi-layer okanye i-disc ye-sintered metal powder okanye i-multi-layers mesh yesinyithi kunye ne-sintered fiber okanye i-sintered metal mesh, njl. ngokwenqanaba lokuhluza olwahlukileyo olusekwe kwiimfuno zeemveliso zokugqibela.

Ngokubanzi kukho iintlobo ezahlukeneyo zenkqubo yokucoca, njengenkqubo yokucoca eqhubekayo eHorizontal, inkqubo yokucoca eqhubekayo ngokuthe nkqo.Ngokomzekelo, ngexesha le-PET chips ukujikeleza inkqubo, uhlobo lokucoca uhlobo lwekhandlela oluthe nkqo lucetywa ngokuqhelekileyo, olunendawo yokucoca ye-0.5㎡ nge-candle core.Kukho ulungelelwaniso oluqhelekileyo olusetyenziswayo lwe-2, 3, okanye i-4 ye-candle cores, ehambelana neendawo zokuhluza ze-1, 1.5, okanye i-2㎡, kunye ne-melt filtration capacities ehambelanayo yi-150, 225, 300 kg / h.Inkqubo yokuhluza ngokuthe nkqo inobungakanani obukhulu kunye nokusebenza okuyinkimbinkimbi, kodwa ineenzuzo ezininzi kwimbono yenkqubo: (1) Inomthamo omkhulu we-thermal, ukuhluka kweqondo lokushisa elincinci lokunyibilika, kwaye akukho mimandla efileyo xa izinto zihamba.(2) Isakhiwo sejacket yokugquma sinengqiqo, kwaye ubushushu bufana.(3) Kukulungele ukuphakamisa undoqo wokucoca xa utshintsha isihluzo.

Umahluko woxinzelelo phambi nasemva kwesihluzo esandula kusetyenziswa sisezantsi.Njengoko ixesha lokusebenzisa lisanda, imingxunya ephakathi kokucoca iyavaleka ngokuthe ngcembe.Xa umahluko woxinzelelo ufikelela kwixabiso lokumisela, umzekelo, njengee-PET chips ezijikelezayo, ngokuqhelekileyo inani limalunga ne-5-7MPa, igumbi lokucoca kufuneka litshintshwe.Xa umlinganiselo woxinzelelo ovunyelweyo ugqithisiwe, i-mesh ye-filter inokuthi iguqulwe, i-mesh size inyuke, kwaye ukuchaneka kokucoca kuncipha kuze kube yilapho i-filter medium igqabhuka.Undoqo wokucoca kufuneka ucocwe phambi kokuba usetyenziswe kwakhona.Ukucaca kwesiphumo kugqitywe ngcono luvavanyo lwe-"bubble test", kodwa inokugwetywa ngokusekelwe kumahluko woxinzelelo ngaphambi nasemva kwesihluzo esitsha esitshintshwayo.Ngokuqhelekileyo, xa isihluzo sekhandlela siqhekeziwe okanye sihlanjululwe ngamaxesha angama-10-20, akufanele siphinde sisetyenziswe.

Umzekelo, kwizihluzi ze-Barmag NSF zothotho, zifudunyezwa ngumphunga we-Biphenyl kwibhatyi, kodwa ubushushu bobushushu bokuhambisa ubushushu akufuneki budlule kwi-319 ℃, kwaye olona xinzelelo luphezulu lweBiphenyl yi-0.25MPa.Uxinzelelo oluphezulu loyilo lwegumbi lokucoca yi-25MPa.Umahluko omkhulu ovunyelweyo woxinzelelo phambi nasemva kwesihluzi yi-10MPa.

IiParameters zobuGcisa

| Umzekelo | L | B | H | H1 | H2 | LUNGISA(H3) | Isingeniso&Isiphumezo se-DN(Φ/) | Indawo yesihluzo(m2) | Ibar yeSikruru esiFakalekileyo(Φ/) | Inqanaba lokuHamba eliyiliweyo(kg/h) | Isihluzi seZindlu | Isihluzo soMmandla | Ubunzima bubonke(kg) |

| PF2T-0.5B | 900 | 1050 | 1350 | NjengeSiza somthengi | 2200 | 22 | 2x0.5 | 65 | 40-80 | Φ158x565 | Φ35x425x4 | 660 | |

| PF2T-1.05B | 900 | 1050 | 1350 | 2200 | 30 | 2x1.05 | 90 | 100-180 | Φ172x600 | Φ35x425x7 | 690 | ||

| PF2T-1.26B | 900 | 1050 | 1390 | 2240 | 30 | 2x1.26 | 105 | 150-220 | Φ178x640 | Φ35x485x7 | 770 | ||

| PF2T-1.8B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.8 | 120 | 220-320 | Φ235x620 | Φ35x425x12 | 980 | ||

| PF2T-1.95B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.95 | 130 | 250-350 | Φ235x620 | Φ35x425x13 | 990 | ||

| PF2T-2.34B | 1030 | 1200 | 1430 | 2330 | 40 | 2x2.34 | 135 | 330-420 | Φ235x690 | Φ35x485x13 | 1290 | ||

| PF2T-2.7B | 1150 | 1200 | 1440 | 2350 | 50 | 2x2.7 | 150 | 400-500 | Φ260x690 | Φ35x485x15 | 1320 | ||

| PF2T-3.5B | 1150 | 1250 | 1440 | 2350 | 50 | 2x3.5 | 160 | 500-650 | Φ285x695 | Φ35x485x19 | 1450 | ||

| PF2T-4.0B | 1150 | 1250 | 1500 | 2400 | 50 | 2x4.0 | 170 | 600-750 | Φ285x735 | Φ35x525x19 | 1500 | ||

| PF2T-4.5B | 1150 | 1250 | 1550 | 2400 | 50 | 2x4.5 | 180 | 650-900 | Φ285x785 | Φ35x575x19 | 1550 | ||

| PF2T-5.5B | 1200 | 1300 | 1500 | 2350 | 50 | 2x5.5 | 190 | 800-1000 | Φ350x755 | Φ50x500x15 | 1650 | ||